The Causes & Solutions of Two Main types of Noise which is occurred in WD HDDs (Especially Related To L-shape PCBs).Continuous Noise & Clicking Noise

1- The Continuous Noise

Sometimes there is a continuous noise come from WD HDDs mainly with L-shape PCBs

with motor ICs (Smooth 1.3) , (L6278 1.7) & (L6278 1.2).

the noise is like : Trrrrrrrrrrrrrr or Trrrr….Trrrr…Trrrrr

so all we have to do for fixing this problem is:

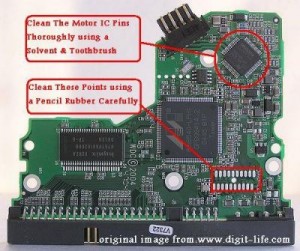

1- clean the connection points which connect the head stack pins with the PCB using a pencil Rubber …carefully.

2- clean the motor IC pins thoroughly using a solvent & Toothbrush then wipe it with a piece of smooth handkerchief to remove the dust & dirt from it.

-Note- the two steps mentioned above solve the problem in few cases.

3- If the two steps mentioned above didn’t fix the problem , you have to replace the motor IC cause it’s damaged.

2-The Clicking Noise

when u power on the hard drive u will hear a noise like (click,click….click,click…click,click)

this noise may be related to the head stack or PCB, the first thing you have to do is to check the PCB By The following steps:

1- first u have to clean the Whole PCB With a Solvent & Toothbrush then wipe it with a piece of smooth handkerchief to remove the dust & dirt from it.

Caution: Cleaning of the PCB must be done carefully to avoid removal of any small electronic components.

2- Check the Resistor (R120) , [ the right value of this Resistor is (0.12 Ohm) ] ,you may adjust your multimeter to Resistor Measuring Mode to Determine its Value ,if it’s Damaged u have to replace it. but before that, u have to check Transistor Q3 , it’s a 6 pins transistor , for measuring this transistor u may adjust your multimeter to Diode Mode,[ the right Value will be: (first two pins = 0.000 , second two pins =0.000 , Third two pins = nearly over 600)]

if Q3 is Damaged it will burn ur R120 after u replace it , so be sure that Q3 is ok before replacing R120 & u may also Check Transistor Q6 by the previous method to be completely sure it’s safe to replace R120.

Note: ( to be sure of The right values of these electronic components u may compare the values u have measured with the values of a working PCB’s Components)

3- Check The Coils (such as L2 & L7) – adjust your multimeter to diode mode then the right value must be ( 0.000 ) for any coil as u all know.

4- Inspect the whole PCB for any removed component ( such as small capacitors or Resistors ) … the removal of these small components may occurred while forced cleaning of the PCB …. so be careful while cleaning it.

5- In rare cases the firmware microchip may be damaged.

——————————————————————————————

-Note- in case of Motor ICs (L6278 1.7) & (L6278 1.2) first try to desolder them then resolder them again before u decide to replace them with a new ones … this sometimes work , but if it didn’t work … replace them directly.

– in case of Motor IC (Smooth 1.3) you must replace it directly.

The image below shows you where to clean.