The spindle motor, also sometimes called the spindle shaft, is responsible for turning the hard disk platters, allowing the hard drive to operate. The spindle motor is sort of a “work horse” of the hard disk, like a heart of human, it give the motivity of power to the HDD. It’s not flashy, but it must provide stable, reliable and consistent turning power for thousands of hours of often continuous use to allow the hard disk to function properly. In fact, many drive failures are actually failures with the spindle motor, not the data storage systems, such as that the motor bearing seizure, Motor not spin.

The spindle motor has several important commitments placed upon it. First, the motor must be of high quality, so it can run for thousands of hours, and tolerate thousands of start and stop cycles, without failing. Second, it must be run smoothly and with a minimum of vibration, due to the strict tolerances of the platters and heads inside the drive. Third, it must not generate excessive amounts of heat or noise. Fourth, it should not draw too much power. And finally, it must have its speed managed so that it turns at the proper speed, neither faster nor slower.

I’ve found that the weather is one of the factors which effect the lifetime of HDD. From some customers from Africa, there are more haunted by the Motor stuck problems than any other places. For some HDD used on server have more demands on the tolerance and quality, they are supposed to be work at 7X24 a week.

To meet these demands, all PC hard disks use servo-controlled DC spindle motors. A servo system is a closed-loop feedback system; this is the exact same technology as is used in modern voice coil actuators. Let’s see how servo systems work in detail. In the case of the spindle motor, the feedback for the closed-loop system comes in the form of a speed sensor. This provides the feedback information to the motor that allows it to spin at exactly the right speed.

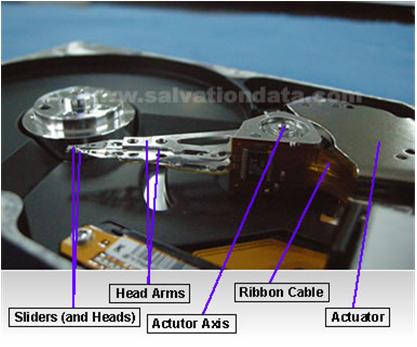

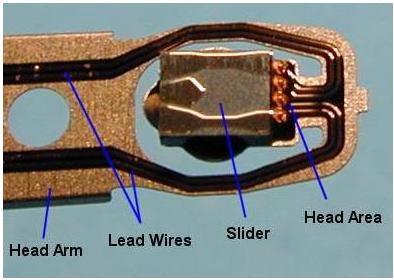

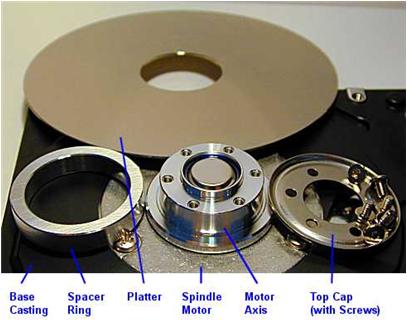

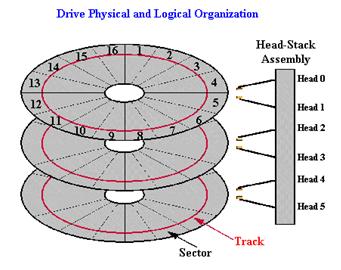

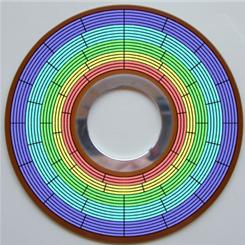

All hard disk spindle motors are configured for direct connection; there are no belts or gears that are used to connect them to the hard disk platter spindle. The spindle onto which the platters are mounted is attached directly to the shaft of the motor. The platters are machined with a hole at the exact size of the spindle, and are placed onto the spindle with separator rings (spacers) between them to maintain the correct distance and provide room for the head arms. The entire assembly is secured with a head cap and usually, lots of small Torx screws.

! By design, TORX head screws resist cam-out better than Phillips head or slot head screws. Where Phillips heads were designed to cause the driver to cam out, to prevent over-tightening, TORX heads were designed to prevent it. The reason for this was the development of better torque-limiting automatic screwdrivers for use in factories. Rather than relying on the tool slipping out of the screw head when a torque level is reached, and thereby risking damage to the driver tip, screw head and workpiece, the drivers were designed to achieve a desired torque consistently. Camcar LLC claims this can increase tool bit life by ten times or more.

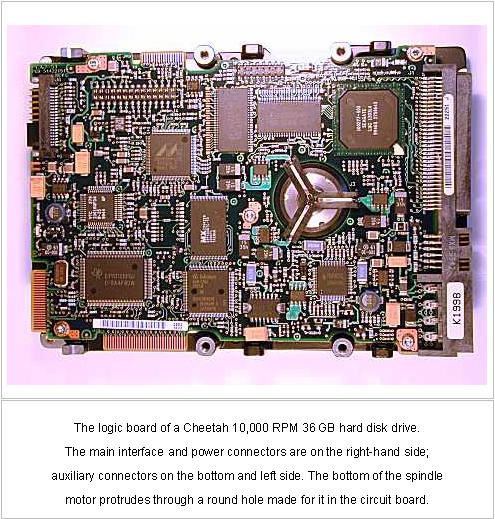

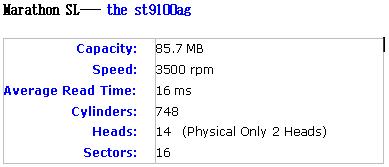

One important quality issue that has become a focus of attention with newer hard disks is the amount of noise, heat and vibration they generate. The reason for this becoming more of an issue is the increase in spindle speed in most drives. On older hard disks that typically spun at 3600 RPM, this was much less of a problem. Some newer drives, especially 7200 and 10,000 RPM models can make a lot of noise when they are running. If possible, it’s a good idea to check out a hard disk in operation before you buy it, to assess its noise level and see if it bothers you; this varies greatly from individual to individual. Heat created by the spindle motor can eventually cause damage to the hard disk, which is why newer drives need more attention paid to their cooling. Newer high-speed drives almost always run cooler and quieter than the first generation of drives at any new spindle speed. It can be painful to be a pioneer;